ProductCategory

ContactUs

- Name:

- Manager Lu

- Tel:

- 0511-88520538

- Fax:

- 0511-88520536

- Addr:

- Huantai Road,New material concentration area,Youfang Town,Yangzhong City,Jiangsu Province

The choice of cable tray must be pay attention to the problem

addtime:2017.03.01

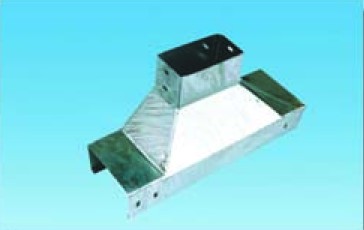

From so many content, and everyone should not ugly out of cable tray is an eternal topic, today is no exception. We all know the types of cable tray is very much, so, so much variety is also very easy to let people the edition. Small make up to today and you talk about when selecting a cable tray must should pay attention to the problem.

First you need to know should be reliable grounding cable bridge device. Such as use of bridge as the grounding line, should be the end of each layer of bridge with 16 was soft copper wire connection (parallel), and total grounding lines are interlinked, long cable tray every 30-50 meters ground again. And its device in addition to the need to screen pack cover, when installation should be outdoors on the top cover, prevent or, for welding installation, the weld around the weldment thickness shall not be less than the thickness of parent metal, joint must be embalmed. Cable cross section in the bridge fill rates: power cable should be not more than 40%; Control cable should not be greater than 50%, for low voltage line can be up to 60%.

Understanding these can see choose cable tray need to consider two important indexes. The bearing capacity of the cable tray work should meet the uniform load, cable tray should be able to adapt to different environmental requirements and has the service life of the imams, typically at present: the bearing capacity of the cable tray is by selecting the appropriate thickness of the material to meet, in order to improve the carrying capacity of the cable bridge, generally the increase and decrease of cable tray plate thickness to achieve; And environmental requirements is heavy corrosion environment generally choose glass fiber reinforced plastic or aluminum alloy as the main body material, the production of cable tray, steel cable tray according to the bridge of the corrosion resistance level and adopt the hot dip galvanized, thermosetting powder electrostatic spray, spray paint, surface treatment, such as electric galvanized.

That is in the choice of cable tray when two of the most important problem, everyone is that clear? When selecting a cable tray must pay more attention to these two points.