ProductCategory

ContactUs

- Name:

- Manager Lu

- Tel:

- 0511-88520538

- Fax:

- 0511-88520536

- Addr:

- Huantai Road,New material concentration area,Youfang Town,Yangzhong City,Jiangsu Province

How to differ hot dip galvanized bridge and electricity galvanized bridge?

addtime:2017.03.03

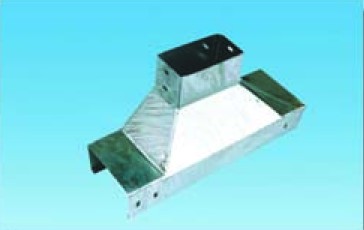

Bridge building materials is the basis of the metal, but place it directly on the natural environment and do not add any protective layer, the metal is easy to react with nature of air and water, corrosion situation, thus affect the sturdiness of the bridge as a whole. Common has a protective layer of bridge types are hot dip galvanized bridge and bridge two galvanized, so the difference between the two bridge is also reflected in what respect? Nanjing bridge manufacturers today and you can talk about the difference between the two.

1, different production process: hot dip galvanized steel or cast into molten zinc liquid zinc - alloy or from forming on the surface of zinc and zinc alloy layer, thereby gaining protective layer, and the electric galvanized steel surface chemical to clean after treatment in the plating solution, direct current (dc) a steel pole, a pole in the plating solution of zinc plate, zinc layer is obtained by the electrode reaction;

2, anticorrosive performance is different: electric galvanized anti-rust effect is not very good, because in the electrolytic reaction of zinc layer, galvanized uneven, and galvanized quantity not enough, usually two or three years will appear rust phenomenon; Hot dip galvanized coating thicker, corrosion resistant ability.

Bridge in the initial installation time, zinc layer are all intact, with the passage of time and the change of external environment, the integrity of the coating and the quality will change, so when after the completion of the bridge engineering, also need regular check and maintenance of the bridge surface, if appear rust, need timely treatment, or rust will expand over time, the overall quality of the project will be affected. On the bridge, in the process of cleaning maintenance, construction should follow the following requirements: (1) temperature with 13 ℃ to 30 ℃ advisable, but shall not be lower than 5 ℃; (2) relative humidity shoulds not be more than 80%; (3) in case of rain, fog, strong wind climate outdoor construction may be undertaken; (4) unfavorable construction under the strong sunlight.